Forklifts are a common sight in warehouses and other industrial settings. They are essential pieces of equipment for moving heavy items around safely. However, with great power comes great responsibility. If not used correctly, a forklift can cause serious injury or even death and there are numerous hazards you should think about. In this blog post, we will discuss 17 forklift safety tips to help you avoid disaster.

Before we dive into the 17 safety tips let’s take a look at the most common hazards that forklift truck operators face, by knowing the potential hazards you can do your best to eliminate or avoid them.

The 5 Most Common Hazards For Forklift Operators

Poor Visibility – When moving a load on a forklift, it is important to have a clear view of what is in front of you and behind you. If the load blocks your view, it increases the risk of an accident.

Blind Spots – All vehicles have blind spots, but forklifts have larger blind spots than most due to their size and design. Be aware of these blind spots and avoid them when driving.

Overloading – Never overload the forks or the cab of the forklift. This can lead to unstable loads and tipping over.

Speeding – Just like any other vehicle, speeding on a forklift can lead to accidents. Take your time and drive at a safe speed.

Distractions – Don’t let anything distract you when operating a forklift. This means no cell phones, no talking to others, and no listening to music.

Now that we’ve gone over the most common hazards, let’s get into the safety tips.

1. Understand The Forklift Classes

Before operating a forklift, it is important to understand the different classes of forklifts. There are three main classes:

Class I – Electric motor rider trucks

Class II – Internal combustion engine rider trucks

Class III – Electric motor hand trucks

Each class of forklift has its own set of safety rules that must be followed, before operating a forklift of a different class ensure you are certified to do so and have a valid licence. If you are ever unsure, always speak to your supervisor, and any good employer will send you for further training before asking you to operate new machines.

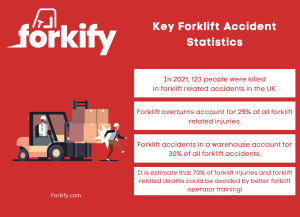

2. Understand The Accident Stats

Forklifts are involved in around 85,000 accidents every year in the United Kingdom. Of these accidents, 123 forklift fatalities occurred in 2021/22 according to the governments HSE. The most common type of accident is a pedestrian being struck by a forklift, so always be aware of your surroundings.

Forklift truck accidents cost businesses a fortune that’s why all modern warehouses have top-tier safety policies in place.

Roughly 70% of accidents can be avoided with proper training, and this brings us to our next tip.

3. Invest In Operator Training And Development

All new operators must be properly trained and develop their skills before being allowed to operate a forklift unsupervised.

As well as training to get a forklift licence all operators should take regular refresher training and additional training for new forklift equipment or different forklift classes.

There are many online courses available as well as in-person classes that supplement training forklift operators do when they get their licence, ensuring your employees do proper forklift training is not only the law but it’s good business sense.

4. Regularly Inspect Equipment

Another crucial part of forklift safety is regularly inspecting the equipment. This includes not only the forklifts but also the loads being moved, the load-handling devices, and the workplace itself.

Forklifts should undergo daily inspections, and any damage should be reported and repaired immediately. The same goes for any damaged load-handling devices, if they are not in good working condition they could fail and cause an accident.

Daily operational inspections and routine checks are also a legal requirement in the UK, you should check the forklift for any signs of wear, check the seat belt, the truck stability, the operator’s cabin and any emergency switches.

5. Make Visibility A Priority

As we mentioned earlier, poor visibility is one of the most common hazards for forklift operators. You can improve visibility in a few different ways:

- Keep the cab of the forklift clean and free of clutter.

- Make sure all mirrors are clean and in good working condition.

- Wear bright clothing to make yourself more visible.

- Use hazard lights when driving in poor visibility conditions.

- Add mirrors or cameras to any blind spots in the workplace allowing forklift operators to see what’s around the corner and avoid unnecessary collisions.

6. Think About Pedestrians

Warehouses can be fast-paced busy environments, and it’s all too easy for pedestrians to get in the way of a forklift.

There are a few things you can do to avoid contact with pedestrians and pedestrian accidents to keep workers safe you can:

- Install traffic lights or safety signs at intersections and crossings to ease the flow of traffic.

- Use barriers to separate pedestrian walkways from areas where forklifts are operating.

- Make sure all employees understand forklift safety and the importance of safe operations.

- Wherever possible have separate pedestrian and forklift operating areas or limit pedestrian traffic in forklift operation areas.

7. The Use Of Floor Markings

Floor markings and aisle markers are an excellent way of increasing safety in the workplace and reducing the risk of accidents. They can be used to indicate safe walking areas for pedestrians, dangerous areas, and forklift operating areas, As well as to indicate when to use the horn and area speed limits.

Another effective way to use floor markings is in the implementation of a one-way system for forklifts, many modern warehouses do this as a way to significantly decrease the chances of a forklift collision.

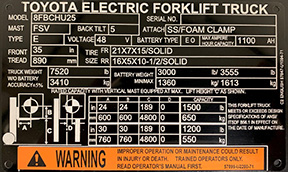

8. Understand Load Capacity

All forklift operators must be aware of the load capacity of their machine as well as the weight and size of the load they are carrying.

Never try to lift a load that is too heavy or too large for the machine, and always use proper lifting techniques. If in doubt, ask for help from an experienced colleague or your supervisor.

9. The Importance Of Correct Clothing And PPE

All forklift operators must wear the correct clothing and personal protective equipment while working. This includes closed-toe shoes, long pants, and a shirt with sleeves. This helps mitigate the risk of minor injuries within a warehouse environment.

Operators should also wear a hard hat, safety glasses, ear protection and high visibility jackets if necessary.

10. Maintaining The Appropriate Speed

All forklift operators must maintain a safe speed while driving, this not only helps to avoid accidents but also ensures the load being carried is not damaged.

When travelling around corners or at intersections always use caution and go slowly to avoid tipping over. In general, it’s best practice to travel no faster than walking pace when there are pedestrians around or when carrying a heavy load.

Always be aware of speed limit signs as there may be physical hazards that you can’t see!

11. Never Allow Passengers

Accidents regularly occur when forklift operators ignore this crucial safety rule and allow passengers on the forks or in the cab. Never allow anyone to ride on a forklift with you, no matter how short the journey, it’s simply a bad idea and not worth the risk.

12. Implement Dedicated Parking And Refuel Areas

Unattended forklifts can be dangerous, that’s why it’s important to have dedicated parking and refuelling areas in the warehouse. This helps to ensure the safety of employees and reduces the risk of accidents.

Refuelling a forklift carries its own set of risks an ever-increasing number of warehouses are switching to all-electric forklifts to mitigate these.

13. Understand The Attachments You Are Using

If you are using attachments on your forklift, it’s important to understand how they work and the potential risks involved. Always consult the operator’s manual before using any attachments, and never use them without proper training.

If your supervisor asks you to use attachments you are unsure of or haven’t used before don’t hesitate to ask for further training.

14. Invest In Proper Lighting

Warehouses can have dark spots if you are managing or working in a warehouse environment and you notice these inform your supervisor.

Most employers will see the potential risks and invest in proper lighting to make everyone’s job safer and easier.

15. Employ The Right People

Your warehouse is only as good as its staff, and that’s why it’s crucial to employ the right people. Those with the necessary experience, training, and qualifications.

Never allow anyone to operate a forklift without the proper certification, it’s simply not worth the risk.

Having great warehouse managers will significantly increase warehouse safety by ensuring everyone is properly trained and aware of the potential risks.

16. Understand How To Safely Secure A Heavy Load

If you are carrying a heavy load, it’s important to understand how to safely secure it. Improperly secured loads are one of the leading causes of forklift accidents.

When in doubt, always ask for help from an experienced colleague or your supervisor.

Unbalanced loads are incredibly dangerous and are often the cause of the most common type of forklift accidents tip-overs

17. Invest In The Right Equipment

There are many different types of forklifts available today and using the right one for the job can increase safety and productivity.

If you are unsure which type of forklift is right for your needs, reach out to one of the Forkify team and we will be more than happy to help.

Investing in the latest safety technology can also help to reduce the risk of accidents in the warehouse. Many modern forklifts come equipped with features like cameras and sensors that can help to avoid collisions.

How To Implement Forklift Safety Solutions

The proper implementation of safety solutions within your warehouse logistics plan will help to create a safer working environment for everyone in the warehouse.

Here are a few tips on how to implement forklift safety solutions:

- Establish clear lines of communication between management and employees.

- Make sure all forklift operators are properly trained and certified.

- Use signs, posters, and other visual aids to remind employees of safety rules and procedures.

- Conduct regular safety audits to identify potential hazards in the workplace.

Conclusion

Operating a forklift is a big responsibility, and it’s important to always be aware of the potential risks. By following the safety tips outlined above, you can help to ensure a safe environment for yourself and your fellow workers.

If you are ever in doubt, always consult with your supervisor!

Remember, safety is always the number one priority.