Forklift battery charging stations are an extremely important part of any successful forklift operation. Having the right charging station for your forklift can help ensure that you get the most out of your truck and keep it running at peak performance. In this article, we will discuss everything you need to know about forklift battery charging stations from what they are to how they should be used. We will also discuss the importance of properly maintained charging stations and the benefits that come with having a high-quality charging station for your forklift fleet.

What Is A Forklift Charging Station?

Forklift battery charging stations are specialized pieces of equipment designed to provide a safe, efficient, and reliable way to charge forklift batteries. These charging stations generally come in two varieties: stationary and portable. Stationary charging stations are typically bolted to the floor of a warehouse, while portable charging stations can be moved around as needed.

How Do Forklift Battery Charging Stations Work?

Forklift battery charging stations work by converting AC power from the wall into DC power that can be used to charge forklift batteries. This process is typically done automatically, with the station detecting when a battery needs to be charged and providing the necessary power. The charging station also helps ensure that batteries are not overcharged, preventing them from becoming damaged or failing prematurely.

The Benefits Of Using A Forklift Battery Charging Station

There are many benefits to using a forklift battery charging station, including improved safety and reliability. Having the right charging station for your forklift can help ensure that you get good forklift battery life and the batteries are ready for use when needed.

There are many benefits to using a forklift battery charging station, including improved safety and reliability. Having the right charging station for your forklift can help ensure that you get good forklift battery life and the batteries are ready for use when needed.

This can improve safety by reducing the risk of accidental discharge or overcharging, as well as improving the reliability of your electric forklift truck operation. Additionally, having a proper charging station can help save time and money by reducing battery maintenance costs.

Forklift Charging Station Requirements

When it comes to electric forklift battery charging stations, there are a few basic requirements that must be met, depending on where you live the legal requirements may differ slightly but the best practices remain the same.

Here’s what you need to know:

Forklift Charging Station Power Requirements

The power requirements for a forklift battery charging station can vary depending on the type of batteries being charged. Generally speaking, a good rule of thumb is to select a charging station with at least 20 percent greater capacity than the batteries that are going to be charged. This will ensure that the station has enough power to charge all of the batteries in your forklift fleet.

Another important consideration is the type of battery being charged. Different batteries require different levels of current and charging stations must be able to provide the necessary level for the given battery. For more information on forklift battery types, you can read our full guide here.

Forklift Charging Station Safety Requirements

In addition to power requirements, it is important to ensure that your forklift battery charging station meets all applicable safety standards and you understand the safety risks. Make sure the charging station you choose is UL-listed and CSA certified for use in your area.

Here are 11 safety tips you should consider to ensure operator safety in your forklift charging area:

Designated charging area

Set up a designated battery charging station in a well-ventilated area, away from flammable materials and ignition sources.

Proper ventilation

Ensure that the charging area is properly ventilated to ensure good air quality and prevent the build up of hydrogen gas, which can be explosive if not adequately dispersed. Most material handling operations use exhaust fans and hydrogen gas detectors to ensure hydrogen levels do not become hazardous for operators.

Fire extinguisher

Place a suitable fire extinguisher close to the charging station, ensuring it is easily accessible, regularly inspected and always ready for use in the event of an electrical fire.

Warning signs

Post clear warning signs around the charging area to inform employees of potential hazards and safety precautions.

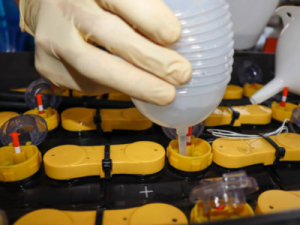

Personal protective equipment (PPE)

Require employees to wear appropriate PPE, such as protective gloves, goggles, and safety footwear, when handling batteries.

Spill containment

Provide spill containment materials, such as acid-resistant flooring and spill kits, to contain any electrolyte leaks or spills. Specialist flooring has fast become the norm for designated battery charging areas.

Electrical safety

Ensure that all electrical components, including forklift battery chargers, cables, and battery connectors, are in good working condition and regularly inspected for damage.

Correct charger type

Use chargers specifically designed for the type of battery being charged. This will prevent overcharging, undercharging, or damage to the battery.

Battery inspection

Regularly inspect batteries for signs of damage, such as cracks, leaks, or swelling, and remove any damaged lead-acid batteries immediately. Battery inspections should be carried out by an appropriately trained member off staff on a daily basis to keep all employees safe.

Employee training

Provide comprehensive training for employees responsible for charging and maintaining forklift batteries, including proper handling, charging procedures, and emergency response.

First aid and eyewash stations

Equip the charging area with a first aid kit and an eyewash station in case of accidental contact with battery acid or hazardous chemicals. Some larger operations also use emergency showers to keep the workforce safe.

Forklift Charging Station Maintenance & Troubleshooting

Just like any other piece of equipment, it is important to properly maintain and troubleshoot your forklift battery charging station. This includes regularly inspecting the cables and connections for loose or frayed wires, checking the power source, and ensuring that the unit is properly grounded.

Just like any other piece of equipment, it is important to properly maintain and troubleshoot your forklift battery charging station. This includes regularly inspecting the cables and connections for loose or frayed wires, checking the power source, and ensuring that the unit is properly grounded.

Additionally, it is a good idea to keep an eye on the charging time for your batteries and make sure that they are not being overcharged.

Whenever a battery is replaced be sure to do thorough checks for manufacturing defects although rare manufacturer defects can cause real damage to your warehouse as well as compromising safety and efficiency

The Importance Of Having A Quality Forklift Battery Charging Station

Having a high-quality forklift battery charger can be incredibly beneficial for any company that relies heavily on its forklift fleet. Not only does it save time and money by reducing battery maintenance costs, but it also improves safety and reliability.

Having the right charging station can help ensure that your batteries are always ready for use when needed. Investing in a quality charging station is an excellent way to ensure that your forklifts remain reliable and efficient for years to come.

Overall, it is important to make sure that your forklift battery charging station meets the needs of your workplace and complies with all applicable safety regulations. By following these tips, you can ensure that your charging station is always safe and reliable. With proper maintenance and troubleshooting, you can trust that your forklifts will be ready when needed.

Selecting The Right Location For Your Forklift Charging Station

To maximize the safety and efficiency of your forklift battery charging station, it is important to select the right location. You should ensure you understand the space requirement needed to accommodate all of the components, As well as being well-ventilated to prevent the build-up of hydrogen gas. Additionally, it should be away from flammable materials and ignition sources. All of these factors are important to consider when selecting the best spot for your forklift charging station.

Final Thoughts

The decision to go full electric and install a forklift battery charging station in your warehouse can seem daunting and it is a big task! Fully understanding your operational requirements is the key, doing so can have incredible benefits for businesses. Not only does it save time and money, but it also helps to improve safety in the workplace. By following the tips above, you can ensure that your charging station is safe and reliable. With proper maintenance and troubleshooting, you can trust that your forklifts will be running smoothly and efficiently for years to come!