In the complex world of warehousing and logistics, order pickers play a critical role. These powerful machines are the backbone of many operations, ensuring that goods are moved efficiently and safely. But what exactly is an order picker? What are its types and uses, and how can you operate one safely?

This article provides a comprehensive overview of order pickers, shedding light on their importance in streamlining warehouse operations. Whether you’re already familiar with warehouse equipment or just getting started, this guide will help you understand the ins and outs of order pickers.

The Definition Of An Order Picker

An order picker is a specialised type of industrial vehicle utilised extensively within warehousing and distribution centres for the purpose of retrieving and transporting materials from storage spaces.

In essence, an order picker acts as an efficient bridge between high-stacked storage and ground-level operations, ensuring a smooth flow of goods within the warehouse. The unique design of this equipment allows it to navigate narrow aisles, making it an invaluable tool in maximising space utilisation and enhancing productivity in storage facilities.

The Different Types Of Order Picker

Order pickers come in three main types to cater to different warehouse needs, including the height of storage racks, the weight of items, and the volume of orders. Here are the main types of order pickers:

- Low-Level Order Pickers: These machines are designed for picking items at lower levels, typically from the ground level up to about 3 metres. They are ideally suited for fast-paced order picking processes where the operator frequently enters and exits the truck.

- Mid-Level Order Pickers: These are designed for medium-height applications. They can typically reach heights of up to about 6 metres and are often used in small to medium-sized warehouses.

- High-Level Order Pickers: These machines can reach heights of over 9 metres and are used in large warehouses with high storage racks. High-level order pickers usually have enclosed platforms for safety.

The Different Order Picker Power Sources

The majority of order pickers are electrically powered, using batteries as a source of energy. The battery voltages can vary, with 24V, 36V, or 48V batteries being common. Here’s a breakdown of the most common power sources for order pickers:

- Lead-Acid Batteries: These are a traditional power source for electric order pickers. Lead-acid batteries are known for their reliability and relatively low cost. However, they require regular maintenance and have a longer charging time compared to other battery types.

- Lithium-Ion Batteries: These batteries are becoming increasingly popular due to their high energy density, fast charging times, and long lifespan. They also require less maintenance than lead-acid batteries. However, they are usually more expensive.

- Internal Combustion Engines: While less common in order pickers, some models may use internal combustion engines (ICE) powered by fuels such as diesel, gasoline, or propane. These are typically used in larger machines and outdoor applications where higher power output and longer runtime are required.

- Manually Operated: Some basic types of order pickers are manually operated, meaning the operator powers the machine by pushing or pulling it. These are typically used for low-level picking and in operations with low volume.

Learn more about forklift fuel types in our comprehensive buyers guide.

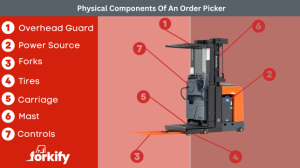

Physical Components Of An Order Picker

Order pickers are complex machines with various physical components that aid in their function. Here is a breakdown of the key components:

- Mast: The mast is the vertical assembly that does the heavy lifting. It’s responsible for raising and lowering the forks and can be single or multi-staged depending on the maximum height requirement.

- Forks: These are the horizontal blades that carry the load. They are adjustable to accommodate different load sizes.

- Operator’s Compartment: This is where the operator controls the machine. It includes the steering mechanism, control levers, and often a seat or standing platform for the operator.

- Power Source: As discussed earlier, this can be an internal combustion engine, a lead-acid or lithium-ion battery, or even manually operated. The power source provides the energy needed to drive the machine and operate the hydraulic system.

- Tires: Depending on the application, order pickers can have either solid rubber tires for indoor use or pneumatic tires for outdoor use. Some models may also have non-marking tires to prevent leaving marks on warehouse floors.

- Safety Features: These can include things like overhead guards to protect the operator from falling objects, safety belts, horns, lights, and other warning devices.

Each of these components plays a vital role in the operation of an order picker, contributing to its efficiency, safety, and overall performance.

The Most Common Uses Of Order Pickers

Order pickers are versatile pieces of equipment that are utilised in various industries for different applications. Here are some of the most common uses:

- Warehouses: Order pickers are fundamental to warehouse operations, where they are used to retrieve and stow inventory for fulfilling customer orders. They are especially useful in warehouses with limited space and narrow aisles.

- Retailers: Retail businesses often use order pickers for restocking shelves and preparing orders for shipment or pickup.

- Distribution Centers: In distribution centres, order pickers are used for picking and packing items for dispatch to retailers or direct to customers.

- Fulfilment Centres: These specialised warehouses where online orders are picked, packed, and shipped, rely heavily on order pickers to quickly and efficiently process orders.

- Manufacturing Industries: Order pickers are also used in manufacturing industries for picking materials needed for production lines.

These are just a few examples of how order pickers are used. The flexibility of these machines allows them to be adapted to many different environments and tasks, enhancing efficiency and productivity in a variety of settings.

The Benefits Of Order Pickers

Order pickers bring numerous advantages to warehouse operations and logistics, significantly enhancing efficiency, speed, and productivity. Here are the key benefits:

- Efficient Use of Space: Order pickers are specifically designed to navigate narrow aisles and reach high storage locations. This feature allows them to make more efficient use of warehouse space, maximising the use of vertical storage and reducing the need for wide aisles.

- Speed and Productivity: Order pickers are renowned for their speed in driving and lifting. They can quickly collect products from shelves and storage pallets, which significantly increases warehouse productivity by reducing the time spent on order picking tasks.

- Improved Customer Service: Effective order picking leads to faster delivery of orders with the right items. This efficiency improves customer satisfaction by ensuring timely and accurate delivery, which is particularly crucial in today’s fast-paced e-commerce environment.

- Versatility: Order pickers excel at picking small to medium-sized products and can be used for both high-level and low-level picking. This versatility makes them suitable for various types of businesses and industries, including retail, manufacturing, and third-party logistics providers.

By integrating order pickers into their operations, warehouses and distribution centres can streamline their processes, optimise their space usage, and ultimately deliver a better service to their customers.

The Basics Of Order Picker Safety

Safety is paramount when operating any kind of machinery, and order pickers are no exception. Here are some basic safety guidelines to consider when using order pickers:

- Proper Training: Before anyone operates an order picker, they should receive comprehensive training. This includes understanding the controls, learning how to safely load and unload items, and knowing how to navigate the warehouse environment.

- Regular Maintenance: Regular maintenance checks are essential to ensure the order picker is in good working condition. This includes checking the brakes, steering, warning devices, and lifting mechanisms.

- Safe Speeds: Operators should always drive at a safe speed, especially when navigating corners or narrow aisles. Speeding can lead to accidents and damage to goods.

- Correct Loading: Overloading the order picker can make it unstable and potentially cause it to tip over. Always adhere to the manufacturer’s weight limits and ensure the load is evenly distributed.

- Wear Safety Equipment: Depending on the environment and the nature of the goods being handled, operators may need to wear safety equipment such as helmets, high-visibility clothing, and safety shoes.

- Stay Alert: Operators should be alert at all times, watching out for other workers, obstacles, safety signs and changes in the warehouse environment.

Remember, safety should always be the top priority. By following these basic safety guidelines, you can help prevent accidents and create a safer working environment.

How To Choose An Order Picker

Selecting the right order picker for your warehouse operations can significantly improve efficiency and productivity. But selecting the wrong machine can lead to hours of headache and additional costs in the future. Here are some key considerations when choosing an order picker:

- Understand Your Requirements: Identify what you need the order picker for. Consider factors like the size and weight of the items you’ll be picking, the height of your storage racks, and the layout of your warehouse.

- Consider the Load Capacity: Different order pickers have different load capacities. Choose one that can safely handle the weight of the items you’ll be moving.

- Evaluate the Lift Height: The order picker should be able to reach the highest shelves in your warehouse. Check the maximum lift height of the machine before making a purchase.

- Check the Battery Life: If your operations run for long hours, you’ll need an order picker with a long battery life or quick charging capabilities.

- Look at Safety Features: Safety is paramount. Look for features like anti-slip platforms, safety harness points, and automatic speed reduction when cornering.

- Consider the Price: While it’s important not to compromise on quality and safety, you should also consider your budget. Use Forkify to compare prices from different local dealers to ensure you’re getting the best value for your money.

Take a look at our comprehensive buyers guide for a complete list of questions to ask and checks to make before buying an order picker.

Final Thoughts

Choosing and operating an order picker can significantly enhance the efficiency, speed, and productivity of a warehouse. By understanding your specific needs, considering factors such as load capacity, lift height, and safety features, you can select an order picker that is tailored to your operations.

Furthermore, adhering to basic safety guidelines ensures not only the smooth running of operations but also the well-being of your staff. The investment in an order picker, when chosen wisely, can yield impressive returns in terms of improved customer service, versatility in operations, and overall business growth.

As with all business decisions, careful research, planning, and consideration are key to making the most out of your warehouse operations.