Summary

- Discover the different types of batteries commonly used in forklifts

- Learn about the characteristics of different batteries

- Find out which battery type is best suited to your application

Electric forklifts are a crucial part of many businesses and operations, as they allow for efficient and effective material handling. However, like any piece of equipment, forklifts require regular maintenance to ensure that they are continuously running at their best. One important aspect of maintaining a forklift is choosing the right type of battery. In this guide, we will explore the three main types of forklift batteries: lithium-ion, absorbed glass mat (AGM), and flooded lead-acid. We will discuss the unique characteristics of each type and provide some guidance on which one might be best for your specific needs.

Lithium-Ion

Lithium-ion batteries may be more expensive than other types of batteries, but they are gaining popularity in forklifts due to their low maintenance needs and improved safety for workers. These batteries can charge quickly, which can improve forklift productivity, and they are also much lighter than other kinds of batteries. Despite their high cost, the advantages of lithium-ion batteries make them a compelling option for many forklift users.

Electric lithium-ion forklift being charged

When using lithium-ion batteries, it is important to follow certain safety guidelines. Always use the correct charger and only buy batteries from reputable sources. Allow the batteries to cool down before attempting to recharge them, and charge them on a stable, well-ventilated surface. Avoid using or charging damaged batteries, and never expose them to high heat. Make sure to power down charging equipment when not in use, and never store fully charged batteries. By following these tips, you can help prevent fires and ensure the safe use of lithium-ion batteries.

Pros of lithium-ion batteries

- Low maintenance

- Lightweight and easy to handle

- High energy for space/weight used

Cons of lithium-ion batteries

- Expensive, although cheaper than previously

- Requires different training compared to lead-acid handling

- Can be dangerous if abused or used incorrectly, such as extreme temperatures

Learn more about lithium batteries here.

Find Your Perfect Forklift

Compare Quotes from Local Forklift Dealerships

Enter Requirements

We Find the Best Deal

Receive your Quote

Lead-acid

Lead-acid batteries are the most common type of battery used in forklifts, but they require regular maintenance. These batteries contain a mixture of sulfuric acid and water, which stores the battery’s energy but can cause damage if the case cracks and leaks. Additionally, lead-acid batteries should be charged on a regular schedule, and the temperature of the charging area should be carefully controlled. To learn more about forklift battery charging stations you can read our full guide here. Proper maintenance and charging can help extend the life of lead-acid batteries.

To keep your lead-acid batteries working at their best, it’s important to have a trained technician test the specific gravity of each cell on a monthly basis. This test is done after the battery has been charged, and the ideal specific gravity of a fully charged battery varies depending on the type and manufacturer. It’s a good idea to check the documentation for your particular battery to find out what the ideal specific gravity should be. This monthly test is also a good opportunity to inspect the cables and connectors for any signs of damage, and to clean the battery case with a battery-neutralizing cleaner. By following these simple steps, you can help extend the life of your lead-acid batteries.

Pros of lead-acid batteries

- Lead-acid batteries are the most common type of battery used in forklifts.

- They are relatively inexpensive compared to other types of batteries.

- When properly maintained, lead-acid batteries can last for many years.

- They are tolerant of cold weather

Cons of lead-acid batteries

- Lead-acid batteries require regular maintenance and watering.

- They can be heavy and difficult to handle.

- If the battery case cracks or leaks, it can cause damage and pose a safety hazard.

- Lead-acid batteries are susceptible to sulfation, which reduces their performance and lifespan.

- They are not as energy efficient as other types of batteries, and can take a long time to charge.

Absorbed Glass Mat (AGM)

AGM batteries are known for their high power output and quick recharging time. They can be charged up to five times faster than a lead-acid battery with the right equipment. AGM batteries also hold a charge well, so they don’t need to be topped off frequently. Unlike lead-acid batteries, AGM batteries don’t require a booster charge to prevent sulfation. Charging an AGM battery is a straightforward process, but it’s important not to overcharge the battery as this will reduce its lifespan. For best results, use the battery until it reaches about 50% capacity, then fully charge it. AGM batteries will start to lose their charging capacity after a few years, even with proper care.

Pros of AGM batteries

- AGM (Absorbed Glass Mat) batteries are sealed, making them low maintenance and spill-proof.

- They are lighter and more compact than lead-acid batteries, making them easier to handle and transport.

- AGM batteries are more energy efficient than lead-acid batteries, and can charge faster.

- They are more resistant to damage from high temperatures, vibration, and deep discharging.

Cons of AGM batteries

- AGM batteries are more expensive than lead-acid batteries.

- They are not as widely available as lead-acid batteries, and may be harder to find in some locations.

- AGM batteries are not as robust as lead-acid batteries, and can be damaged by overcharging or excessive discharge.

- They may not last as long as lead-acid batteries, depending on the specific usage conditions.

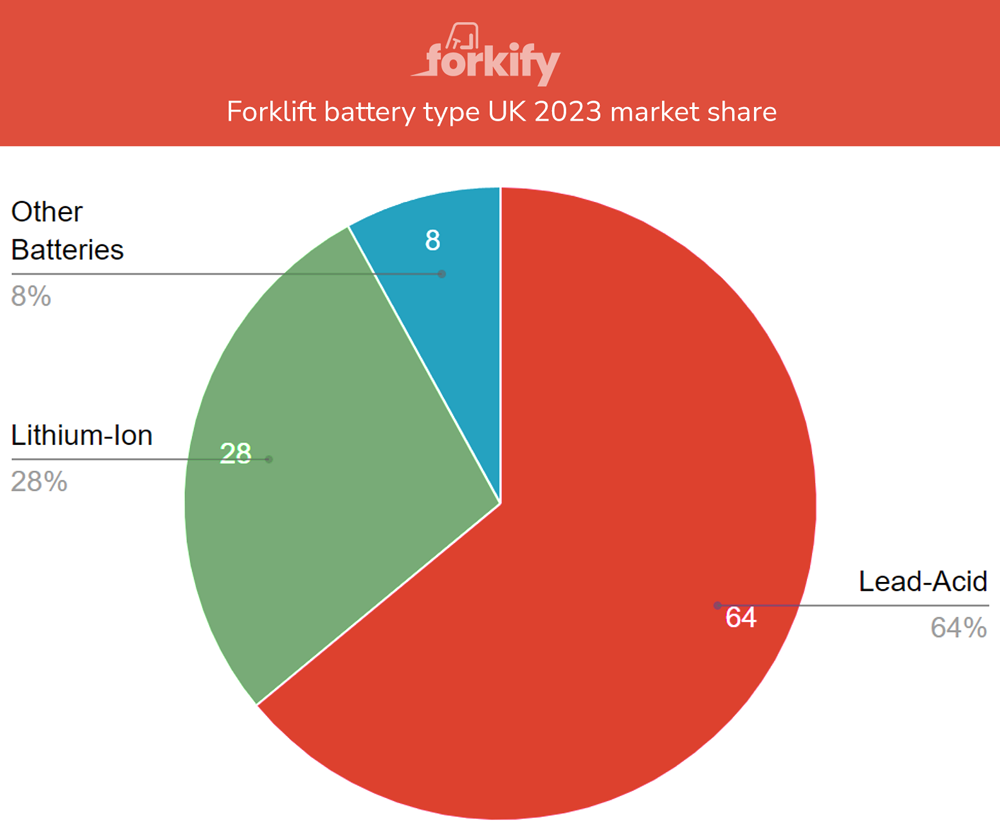

UK Forklift Battery Type Market Share

The types of batteries used in the UK electric forklift market have changed over the past few years, thanks in part to improved lithium-ion technology and a general push to end reliance on fossil-fuel forklifts. Lead-acid still remains the most popular choice, but lithium-ion batteries are quickly becoming more popular.

A pie chart showing the UK market share of forklift battery types. Source: forkify.com

We expect to see lithium-ion forklifts account for 50% of battery types by 2027, with lead-acid continuing to decline and other batteries, such as AGM, to decline slightly.

Forklift battery safety

When working with forklift batteries, it is important to take necessary precautions to ensure the safety of yourself and others. In addition to any site-specific safety measures, you should wear appropriate personal protective equipment, such as gloves, eye protection, and steel-toed boots. Keep safety equipment on hand, such as a first aid kit, sink, and eyewash station. Use the proper equipment to lift batteries, and never try to lift one by hand. Never reinstall a damaged battery with a frayed cable, cracked case, or pronounced corrosion. Additionally, avoid storing batteries in areas that may experience extreme heat or cold. By following these guidelines, you can help prevent accidents and ensure the safe handling of forklift batteries.