Operating a forklift can be a challenging task if you lack knowledge of its basic components. One of the most important parts of a forklift is its mast, which is responsible for lifting and lowering loads. However, different types of masts serve specific purposes.

If you work in an industry that requires the use of forklifts, it is essential to understand the different forklift mast types to ensure safety, efficiency, and optimal performance. So in this article, we’ll discuss everything you need to know about forklift masts to help you make informed decisions while operating, purchasing or renting a forklift.

What Is a Forklift Mast?

In simple terms, a forklift mast is a vertical assembly of parts in the form of a frame that supports the load. It can be used to transport and lift materials up or down in warehouse operations. The mast rests on top of the truck’s carriage and allows operators to raise and lower heavy loads while keeping them secure.

How Do Forklift Masts Work?

Forklift masts usually use hydraulic power to raise and lower loads. The mast is powered by the truck’s hydraulic system, which is activated by a lever or switch inside the cab. When the operator pushes the lever forward, pressurized oil forces the carriage platform upward, lifting the load that it carries. Conversely, when reversed, pressurized oil is released, allowing the mast to descend, and lowering the load.

Find Your Perfect Forklift

Compare Quotes from Local Forklift Dealerships

Enter Requirements

We Find the Best Deal

Receive your Quote

The Components of A Forklift Mast

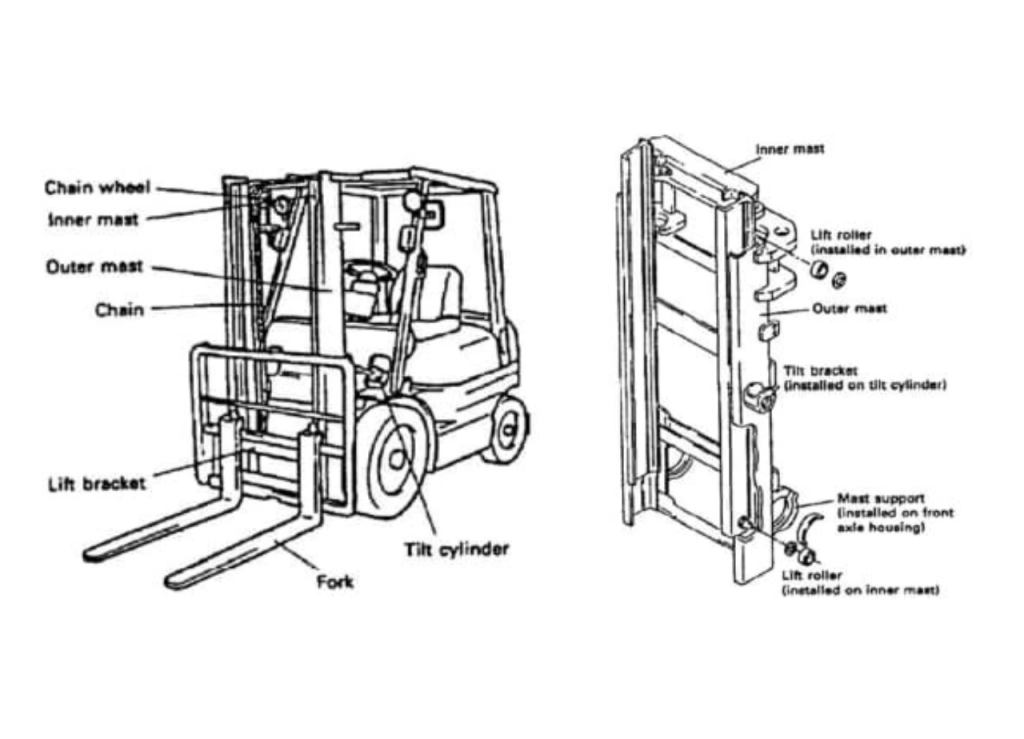

Forklift masts are composed of several mast sections that enable them to function properly. The main components include:

– Mast Cylinders: Also known as hydraulic cylinders or lift cylinders these are the most important elements of a mast and allow the truck to lift and lower loads. They usually consist of telescoping tubes filled with oil and two pistons inside.

– Carriage and Load Backrest: This is part of the mast that holds and carries the load. It is connected to the mast cylinders via hinges and bolts, allowing it to move up and down.

– Rails: The rails are the two vertical bars that provide stability and strength to the mast. They are connected to the carriage and are what allow the truck to extend to its maximum fork height (MFH).

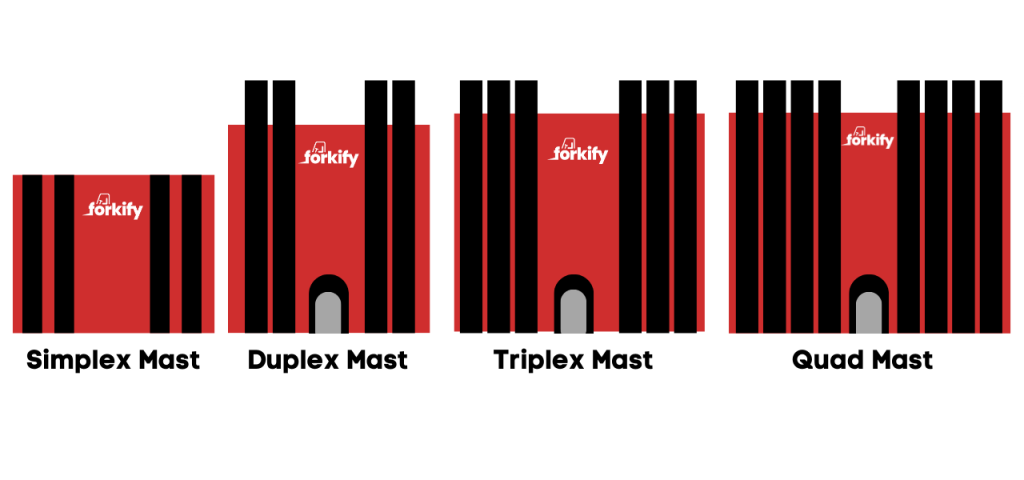

The most common forklifts are two stage mast forklifts but bigger trucks can have four stage masts with four sets of rails!

– Overhead Guard: This is a protective shield that covers the operator in case something falls on them while they are operating the forklift. It also helps prevent objects from being caught in the mast and obstructing their movement.

Image Source: ProLift Toyota Material Handling

Common Forklift Mast Terminology

Free Fork Height (FFH):

The total height of the mast from the floor to the top of the overhead guard when it is not being used to lift a load. This is important to consider when determining the amount of overhead clearance needed for a given application.

Maximum Fork Height (MFH):

The highest point that the forks of the forklift can reach when fully extended. This is essential for reaching tall pallets and other elevated materials.

Fork Spread:

The distance between the two forks when they are extended out. This is important to consider when determining which size of pallet can be safely handled by the forklift.

Overall Mast Height:

The total height of the mast from the floor to the top of the overhead guard when it is being used to lift a load. This is important for determining the maximum lift height that can be safely handled by the forklift.

Overall Lowered Height:

The total height of the mast from the floor to the top of the overhead guard when it is in its lowest position. This is important for determining the minimum load height that can be safely handled by the forklift, As well as for storage when not in use.

Types of Forklift Masts

Forklift masts come in a variety of types and styles, each designed for specific applications. The most common mast types are:

– Two-Stage Mast: This is the most common type of mast also known as a “Duplex Mast” and can typically lift loads up to about 20 feet. It consists of two vertical rails that are connected to the carriage and can extend up and down in two stages.

– Three-Stage Mast: Also called a “Quad Mast” This is a variation on the two-stage mast, with an additional stage that extends higher than its predecessor. These masts are typically used for lifting heavier loads up to 30 feet high.

– Telescopic Mast: This type of mast consists of a single telescoping tube that extends upward and is capable of lifting loads to 50 feet high. These masts are typically used for servicing taller machinery or materials, such as aircraft engines.

– Articulating Mast: Also known as “bendable” masts, these consist of several segments that can bend in various directions to allow the forks to reach around obstacles or into tight spaces. These masts are typically used for pick-and-place applications and can lift loads to 16 feet high.

These forklift masts are essential components for any materials handling operation, ensuring that loads can be safely lifted and moved without risk of injury or damage. Knowing the different mast types and their respective capabilities can help you select the best option for your specific application. With this knowledge, you can ensure that your operation runs smoothly and efficiently.

Factors To Consider When Choosing A Forklift Mast

With so many different types of mast available, it’s important to select the one that best meets your requirements. Each type has its advantages and disadvantages, so it’s important to consider all of your options before making a purchase. Here are some key factors to keep in mind when selecting a forklift mast:

How High Do You Need To Lift?

First and foremost, you should consider how much weight the mast will be expected to lift and the required lift height. This should include both the weight of the goods and any additional items that need to be moved, such as pallets or containers.

How Much Do You Have To Spend?

Mast types range in price depending on their size and capacity. It’s important to factor in your budget when selecting a mast so that you don’t end up spending more than necessary.

What Kind Of Space Do You Have?

It’s also important to keep in mind the amount of space available for the mast. Forklift masts are typically quite tall, so you need to make sure that there is enough space for them in your warehouse or other location.

Where Will You Operate?

Will the forklift be used for outdoor applications or only indoors? If it will be used in an outdoor environment, consider selecting a mast with weatherproofing features, such as a sealed-in motor.

If moving your forklift in and out of buildings for loading or other applications also consider the height of the doorways and the overhead clearance needed, make sure you select a mast that is low enough to fit through.

How high do you need the forklift to lift materials?

This one seems obvious but is often overlooked. Make sure that you look at the limited lifting height and lift capability to ensure it is suitable for your warehouse applications.

By knowing the various types of masts available and factors to consider when selecting one, you’re better equipped to find the perfect mask for your operation. With the right mast in place, you can ensure that your materials handling operations run smoothly and safely.

How To Avoid Forklift Mast Accidents

Safety should always be the top priority when using any type of forklift. To avoid accidents, there are several key steps you can take.

Make sure all drivers are properly trained and certified to operate the forklift. Ensure that operators always follow safety regulations and wear protective gear such as hard hats, gloves, and goggles when needed.

Also, inspect the mast before each use to make sure that it’s in proper working order. Pay special attention to any worn or defective components and replace or service them as needed.

Finally, be aware of your surroundings when operating a forklift with a mast. Follow all traffic signage and ensure that other personnel in the area are aware of what you are doing.

By following these simple steps, you can help protect yourself, your employees, and any materials that you’re handling from potential harm.

Final Thoughts

Forklift masts come in a variety of shapes, sizes, and capacities. It’s important to consider your specific needs before selecting one so that you can make sure you have the right mast for your application.

By understanding the different types of masts available, as well as the factors to consider when selecting one, you’ll be able to find the perfect mast for your operation and ensure that it is used safely.

With the right forklift mast in place, you can maximize the efficiency of your business operations and keep everyone safe at the same time.