Scissor Lift Hire & Sales

Find the best prices on scissor lifts from your local dealers.

We’ve helped customers find the best deals in their area

The new way to buy and hire forklifts

We simplify the forklift hire and sales process and save you money! Instead of spending hours researching and contacting local dealers individually, let Forkify do the heavy lifting for free!

Connect with Certified Local Dealers

Enter your requirements and we'll find suitable dealers in your area.

We Find the Best Deals

We search and compare deals from your local dealer to ensure you get the best price.

You'll See Your Savings

We put you in touch with dealers that provide the best value for money, meaning more savings for you.

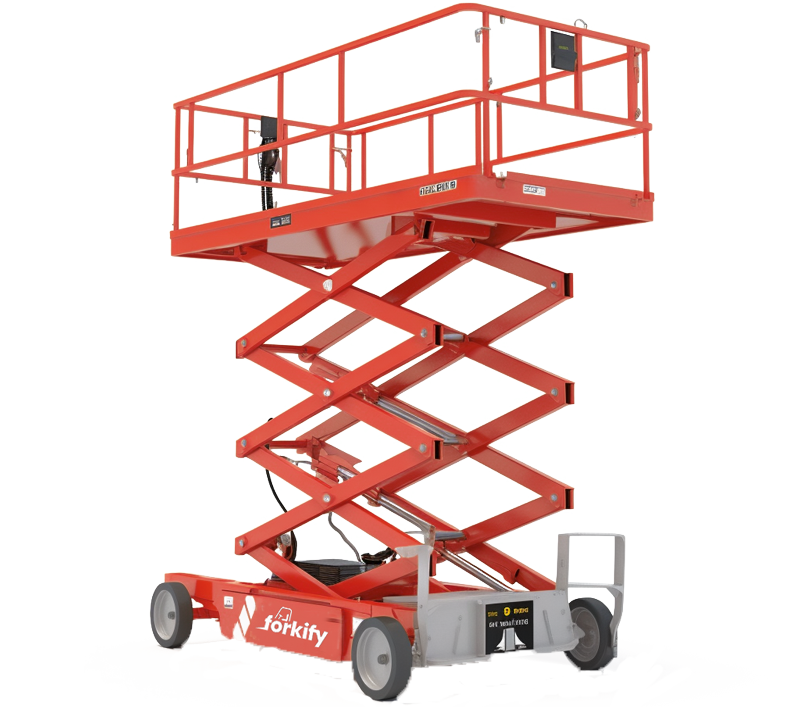

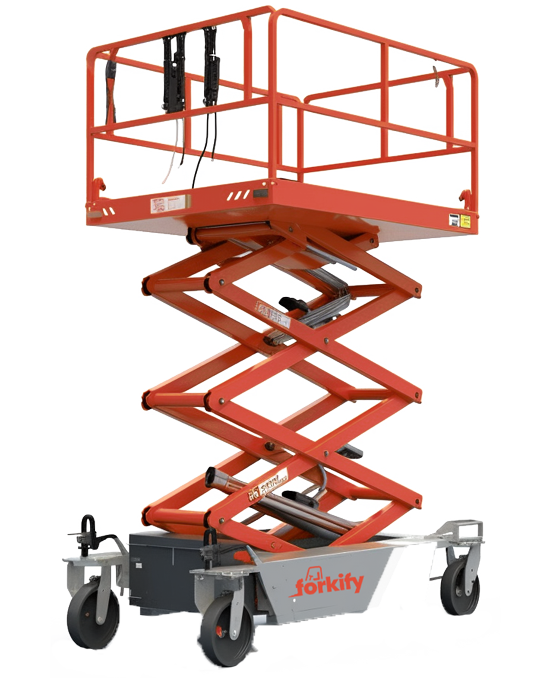

What is a Scissor Lift?

A scissor lift is a type of manlift commonly used in facility and construction applications. It is designed to lift workers and tools to heights that range from 5.9m to 17.9m using a lifting mechanism that functions like scissors when the platform is raised and lowered.

Scissor lifts are typically self-propelled machines and can be classified as slab scissor lifts or rough terrain scissor lifts based on their intended application. Slab scissor lifts have solid, non-marking tires and are designed to operate on concrete slabs. These machines are compact and highly maneuverable, making them ideal for use in tight spaces.

Top Scissor Lift Types

Pneumatic Scissor Lifts

A pneumatic scissor lift operates using air pressure, without reliance on electrical or hydraulic systems. It is raised and lowered using air alone, making it a highly clean and low-maintenance option. This lift is particularly suited to environmentally conscious projects, due to its eco-friendly design.

Pneumatic scissor lifts are also extremely versatile, as they do not require electricity to operate. This makes them suitable for use in areas that are prone to explosions or extreme temperatures.

Hydraulic Scissor Lifts

Hydraulic scissor lifts use either compressed air or an electric motor as a power source, allowing the lift to be raised or lowered by pushing or draining hydraulic liquid from cylinder to cylinder.

These lifts can be used both indoors or outdoors, and are well-suited for operations on construction sites, infrastructure projects, and in warehouses. While they offer more lifting power compared to pneumatic scissors, they also pose a greater risk of environmental leaks.

That being said, hydraulic scissor lifts remain a popular choice for those who require heavy lifting capabilities, and they can be found in a variety of industries.

Truck-mounted Scissor Lifts

A truck-mounted scissor lift is a type of lift that is mounted on a truck, providing users with high levels of flexibility and mobility. This allows the lift to be easily moved from one location to another, making it an ideal solution for tasks that require work to be carried out in multiple locations, such as streetlight maintenance or traffic signal work.

Truck-mounted scissor lifts are typically powered by the truck’s engine, although battery-powered models are also available. These lifts offer significant advantages over other types of lifts, as they are highly mobile, efficient, and cost-effective.

Find Your Scissor Lift Now

How Much Does a Scissor Lift Cost?

*based on 7 day hire in the UK

,

Top Uses For Scissor Lifts

Indoor Maintenance In Spaces With High Ceilings

Buildings like hospitals, libraries, and schools often have high ceilings that can be difficult to access safely using ladders alone. Scissor lifts offer a reliable, safe solution for maintenance work at such heights, enabling workers to bring all their tools and equipment with them.

Sign Maintenance

In sign maintenance, one of the key benefits of scissor lifts is that they can be used on uneven or sloped terrain, making them particularly useful for sign maintenance on outdoor signs located on hills or rough terrain. They provide a stable platform for workers to conduct the necessary work and can be fitted with additional features like extendable platforms to provide additional reach.

Warehouse Organisation

In a warehouse environment, safety is paramount, and scissor lifts offer several features that cater to this need. They are stable, sturdy and provide a secure platform for workers to carry out tasks at height. This is particularly important in areas with high traffic or where workers need to operate heavy machinery.

Scissor lifts are also well suited for warehouses due to their compact design, making them easy to maneuver in tight spaces where other equipment may struggle to operate.

Scissor Lift Specification

| Lift Height | 3-6 m |

| Load Capacity | 3000-10000 KG |

| Lift Duration | 30-90 s |

| Weight | |

| Dimensions (L x W) | 2m x 1.2m |

| Ground Clearance | 300-800mm |

What Our Expert Says

“Scissor lifts are ideal for those hard-to-reach places, and consequently have a wide range of uses. They can often eliminate the need for scaffolding, potentially saving you thousands of pounds.”

Will Bradley, Co-Founder at Forkify

Should I Buy or Hire a Scissor Lift?

Whether to buy or hire a scissor lift depends on various factors, including your business needs and long-term plans. While purchasing a scissor lift may seem cost-effective in the long run, the ongoing costs of maintenance and inspections may add up over time.

Before making a purchase, it’s important to ensure that the scissor lift is suitable for all the spaces in which you need to use it, considering the working height requirements for all the envisioned tasks.

Alternatively, renting provides the flexibility to try out different machines and choose the most appropriate one for the task at hand, without worrying about the costs associated with repairs, storage, and maintenance. This may be especially beneficial for businesses that require access to scissor lifts for a limited time or for occasional use.

Ultimately, the decision to buy or hire a scissor lift should be based on the specific needs and budget of your business, taking into account the intended usage and frequency of use.

How Does It Work?

Let Forkify simplify your search for the perfect scissor lift deal! Just input your needs and we’ll gather offers from nearby dealers. Say goodbye to the hassle of finding the right deal and let us do the heavy lifting for you.

Popular Scissor Lift Brands

Frequently Asked Questions

Who Makes The Best Scissor Lifts?

There are several companies in the UK that manufacture high-quality scissor lifts. Some top manufacturers include Genie, JLG, Haulotte, and Skyjack. These companies offer a range of scissor lifts designed to meet different lifting needs, including indoor and outdoor applications, rough terrain, and more. Ultimately, the best scissor lift for your specific needs will depend on your budget, application requirements, and other factors, so it’s important to do your research and compare options before making a purchase.

Forkify makes this easy by having a handful of vetted dealers come to you!

How High Can Scissor Lifts Reach?

Scissor lifts come in various sizes and types, and their maximum reach height can vary depending on the model. Generally, scissor lifts can reach heights of between 6 and 18 meters (20 to 60 feet), with some models capable of reaching even higher elevations. However, it’s important to note that the maximum height of a scissor lift will also depend on its weight capacity and other factors. For safety reasons, it’s recommended to always use a scissor lift within its intended height and weight limits.

How Often Do Scissor Lifts Need To Be Inspected?

In the UK, scissor lift inspections are required by law under the Lifting Operations and Lifting Equipment Regulations (LOLER) 1998. According to LOLER, scissor lifts should undergo a thorough inspection every six or twelve months, depending on the lift’s age and usage.

A competent person or a company that specialises in inspections should carry out inspections. All inspections should include a visual inspection of the lift, as well as functional testing of critical components. Any defects or issues should be noted and addressed immediately.

In addition to LOLER inspections, daily pre-use inspections are also recommended in order to identify any potential issues or malfunctions that could compromise the safety and performance of the scissor lift. These inspections should be carried out by the operator before each use of the lift, and documented in a checklist.

What Is The Difference Between a Scissor Lift and a Boom Lift?

Scissor lifts and boom lifts are both types of aerial work platforms used to provide elevated access for workers and equipment. While they might appear to be similar in function, there are several differences between the two types of lifts.

-

Lifting mechanism: A scissor lift uses a series of crossed bars (the “scissor” mechanism) to extend the platform vertically, while a boom lift uses a hydraulic arm to extend the platform both vertically and horizontally.

-

Manoeuvrability: Boom lifts can typically rotate 360 degrees or more, allowing for greater mobility and flexibility when working around obstacles. Scissor lifts are generally less versatile in their movement and are better suited for vertical travel.

-

Reach and height: Boom lifts have a greater reach and height than scissor lifts, with some models capable of reaching up to 185 feet. Scissor lifts are typically limited to heights of 20 to 50 feet.

-

Weight capacity: Boom lifts generally have a higher weight capacity than scissor lifts, with some models capable of supporting up to 1000 pounds. Scissor lifts are typically limited to weight capacities of 500 to 1000 pounds.

Overall, the choice between a scissor lift and a boom lift will depend on the specific needs of the task at hand, including the required height, weight capacity, and manoeuvrability.

What Are Scissor Lifts Usually Used For?

Scissor lifts are versatile pieces of equipment that are used in a variety of settings, including construction sites, warehouses, factories, and entertainment venues. Some specific applications of scissor lifts include:

- Installing and repairing electrical systems and lighting fixtures

- Painting, cleaning, and maintaining buildings and equipment

- Stocking and retrieving goods in warehouses and distribution centers

- Conducting inspections and repairs of high structures

- Setting up and dismantling event stages and equipment

- Filming movies and TV shows to get the perfect shot

- Conducting building surveys

- Facilitating access to hard-to-reach areas during construction work

Overall, scissor lifts are ideal for tasks that require elevation and stability, making them a safe and efficient solution for a wide range of applications.

What Is The Smallest Scissor Lift?

The GENIE GS1330 is regarded as the smallest scissor lift on the market at the time of writing with a length of 1.4 m and breadth of 0.78 m. It has a 5.9 m working height and can even fit through a normal doorway.