Electric forklifts are becoming more and more common. With their quiet operation, zero emissions, and lower operating costs, they’re an attractive choice for many businesses.

However, one question that often arises is, “How much do they cost?” This is a critical factor to consider when planning your investment, as the pricing can vary significantly depending on several factors. In this article, we’ll delve into the world of electric forklift pricing, examining the costs of new and used models, factors influencing the price, and tips on finding the right forklift for your budget.

Whether you’re a small business owner looking to streamline your operations or a large corporation seeking to reduce your carbon footprint, this comprehensive guide will provide you with the insights you need to make an informed decision.

Note, if you’re looking for more general forklift pricing information, check out our dedicated pricing guide.

How Much Does An Electric Forklift Cost?

The cost of an electric forklift can fluctuate significantly based on various factors. However, the most glaring difference in pricing typically lies between new and used electric forklifts.

New Electric Forklifts

In the UK, the pricing for a new, standard capacity electric forklift generally falls within the range of £10,000 to £30,000. For models boasting higher capacities or advanced features, prices can escalate, potentially exceeding £40,000.

Used Electric Forklifts

If you’re working with a tighter budget, buying a used electric forklift can be a cost-effective alternative. While the exact pricing can depend on the lift’s age, condition, and usage hours, used models typically cost significantly less than new ones. Expect to pay anywhere from £5,000 to £20,000 for a used electric forklift.

Find Your Perfect Forklift

Compare Quotes from Local Forklift Dealerships

Enter Requirements

We Find the Best Deal

Receive your Quote

What Factors Affect The Cost Of An Electric Forklift?

The overall cost of an electric forklift is not a fixed figure; it varies greatly, influenced by a multitude of factors that make every purchase a unique investment. Here are the key elements to consider:

Type Of Forklift

The specific model and type of the forklift play a significant role in determining its cost. Different types have different capabilities and therefore, different price points:

Electric Counterbalance Forklifts

These are the most common type of forklift. They use a counterbalance weight design to offset the load being lifted, which allows for straightforward operation. As of 2023, the price for a new electric counterbalance forklift in the UK ranges from £20,000 to £30,000 depending on the brand, lift capacity, and any other specifications.

Electric Narrow Aisle Forklifts

Designed to operate in tight spaces, these forklifts are perfect for warehouses with high-density storage. The price for a new electric narrow aisle forklift typically ranges from £20,000 to £35,000.

Electric Sideloaders

Sideloaders are designed for handling long loads in narrow aisles. They are particularly useful in timber, steel, and construction industries. The cost of a new electric side loader can range from £30,000 to £50,000, based on the specifications.

Electric Order Pickers

These are used in warehouses for picking items from shelving at various heights. The cost of a new electric order picker can vary greatly depending on its height capacity, ranging from £15,000 to £25,000.

Forklift Brand

The brand of the forklift is a significant factor in determining its cost. Different brands have varying reputations for quality, reliability, after-sales service, and innovation, which are reflected in their pricing. Here are some well-known electric forklift brands in the UK, along with the typical price ranges:

Toyota Electric Forklifts:

Known for their durability and high-quality components, Toyota forklifts often command a higher price. However, the superior build quality and excellent after-sales service justify the cost. In the UK, the price of a new Toyota electric forklift can range from £20,000 to £40,000 depending on the model and specifications.

Linde Electric Forklifts:

Linde forklifts are renowned for their innovative features and ergonomic design. While they may be pricier than some brands, many businesses find the advanced capabilities worth the investment. The price for a Linde electric forklift in the UK typically ranges from £22,000 to £45,000.

Hyster Electric Forklifts:

Offering a wide range of models, Hyster forklifts are known for their robustness and reliability. The pricing is competitive, considering the quality and range of options available. A new Hyster electric forklift in the UK could cost between £24,000 and £45,000.

EP Equipment Electric Forklifts:

EP is a major player in the material handling industry, known for its cost-effective and innovative solutions. They offer a wide range of electric forklifts, suitable for various applications. The price for a new EP electric forklift in the UK typically ranges from £14,000 to £30,000.

Lift Capacity

Lift capacity is another crucial factor to consider when purchasing a forklift. It refers to the maximum weight a forklift can lift safely. Overloading the forklift can lead to accidents and damage to the machine. Therefore, it’s important to accurately determine the lift capacity needed for your operations.

Forklifts with a higher lift capacity generally cost more because they require more robust and durable components to handle heavier loads. Here are some typical lift capacities and their approximate cost ranges:

| 1000KG (1 Tonne) | Costs between £13,500 and £20,000 |

| 2000KG (2 Tonne) | Costs between £21,000 to £26,800 |

| 3000KG (3 Tonne) | Costs between £30,000 to £34,500 |

Adaptations or Specific Features

Forklifts can come with a variety of adaptations or specific features to suit different work environments and tasks. These specialised features can enhance the functionality of the forklift, but they can also add to the cost. Here are some common forklift adaptations and their potential impact on price:

- Mast Type: The mast is the vertical assembly that does the work of raising, lowering, and tilting the load. Some forklifts have a simple standard upright mast, while others have a duplex (two-stage) or triplex (three-stage) mast for higher lift heights. A more complex mast will generally increase the price.

- Tire Type: Forklifts can come with cushion tires (for indoor use) or pneumatic tires (for outdoor use). There are also solid rubber tires and non-marking tires for specific applications. The type and quality of the tire can affect the price.

- Cab Features: Enclosed cabs, heating, air conditioning, ergonomic seats, and advanced control panels can make the operator’s job easier and more comfortable, but they can also add to the cost.

- Attachments: There are various attachments available for forklifts, such as side shifters, fork positioners, paper roll clamps, and rotators. These can greatly expand the versatility of the forklift, but they also add to the price.

- Safety Features: Enhanced safety features like backup cameras, blue safety lights, and load stability systems can increase safety but will also increase the price.

Warranty & After-Sales Service

When purchasing a forklift, the warranty and after-sales service are important considerations that can significantly impact the total cost of ownership.

- Warranty: A warranty is a manufacturer’s or dealer’s guarantee to repair or replace parts of the forklift if certain problems arise within a specified period. Warranties can vary greatly in terms of duration and coverage. Some cover only parts, while others cover parts and labour. Some are comprehensive, covering all major components, while others exclude certain parts. The length of the warranty can range from one year to several years.

- After-Sales Service: This refers to the support provided by the dealer or manufacturer after the purchase. It includes things like maintenance services, parts availability, technical support, and training. Good after-sales service can help keep your forklift running smoothly and minimise downtime, which can save you money in the long run.

Remember, a cheaper forklift may end up costing more if it comes with a limited warranty and poor after-sales service. Always compare the warranty and after-sales service when comparing forklift prices.

The Long Term Cost Of Electric Forklifts vs Other Fuel Types

When considering the purchase of a forklift, it’s crucial to consider not only the initial purchase price but also the long-term operating costs. These costs can vary greatly depending on the type of fuel the forklift uses.

Electric forklifts have higher upfront costs due to the cost of the battery and charger. However, they have lower operating costs over time because the batteries can be recharged and require low maintenance.

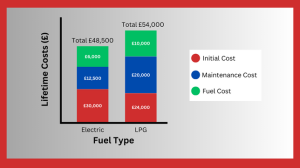

The graph presents a comparative analysis of the expenses associated with Electric and LPG forklifts over a span of 10,000 operational hours, assuming no additional costs for part replacements or repairs. It should be noted that the likelihood of a breakdown is higher in the case of LPG forklifts due to their more complex mechanical structure.

Final Thoughts

In conclusion, the cost of an electric forklift is influenced by various factors including the model, capacity, battery type, and any additional features. While the initial investment may be higher than other fuel type forklifts, the lower operating and maintenance costs can make electric forklifts a more economical choice in the long run.

It’s important to consider not only the upfront price but also the total cost of ownership when evaluating your options. Always remember that investing in an electric forklift is not just about cost, but also about contributing to a cleaner environment and a more efficient and quieter operation.